Patching Cracks In Concrete Floor

- Patching Cracks In Concrete Floor In Crawl Space Video

- Patching Holes In Concrete Floors

- Fixing Cracks In Concrete Basement Floor

- Patching Cracks In Concrete Floor In House

Simply pouring wet concrete into a hole in your driveway, sidewalk, or basement floor won't make for a lasting repair. You have to prep the edges correctly and use the right materials. Holes 1 inch or deeper require a concrete mix with coarse, crushed-stone aggregate, which bonds well with existing concrete. Shallower holes need a sand mix. Whichever type you use (they're both available at home centers), follow these steps.

1. Use a hammer and a cold chisel to level the bottom of the hole and undercut its sides slightly so the patch can't pop loose. Vacuum, then clean the area with water and a wire brush. Wipe clean.

2. Brush on a concrete bonding liquid, sold in bottles at home centers.

3. While the bonding agent is still tacky, mix the concrete with water and scoop some into the hole. Press it into the corners and against the edges with a trowel. Now fill the hole completely, leaving some material mounded on top.

- QUIKRETE Concrete Repair, QUIKRETE Gray Concrete Crack Seal or QUIKRETE Self-Leveling Polyurethane Sealant may be used. Step 1 Widen the crack using a chisel and hammer to a minimum of ¼ inch and break away any deteriorating concrete (the edges of the crack should be vertical or beveled in an inverted “v”).

- How to Repair Cracks in Concrete: Add the resurfacer Spread the resurfacer. Family Handyman. Pour concrete resurfacing mixture into the crack and smooth it out with a rubber floor squeegee. Feather the edges to get the best appearance. Add water to the resurfacer mix to get the consistency of pancake batter for the concrete crack filler.

- Concrete floor patching is your solution to minor cracks that are more about aesthetics, moisture intrusion, and insect infestation than about major structural integrity. Cracks make your basement look bad and they do not help your property's resale value.

- Quikrete 10 lb. Vinyl Concrete Patcher is ideal for making smooth repairs to crack or chipped concrete floors, sidewalks or steps. It has strong adhesive properties allowing it to be applied down to a featheredge. Quikrete 10 lb. Vinyl Concrete Patcher is made of a special blend of vinyl resin, fine sand and Portland cement.

Patching Cracks In Concrete Floor In Crawl Space Video

Patching cracks: Cleaning, chiseling, and patching. Repairing and resurfacing driveways: Step-by-step guide. Sidewalk repair solutions. How to fix cracks in stamped concrete. How to fix cracks before applying an overlay. Low-pressure crack injection for repairing basement and foundation cracks. Step-by-step pictorial overview of how cracks are.

4. Level the patch with a straight-edged board at least a foot longer than the width of the hole. Move it back and forth in a sawing motion. This will also push down the aggregate and make the final smoothing easier. When the surface loses its wet sheen and feels firm to the touch, smooth it with a magnesium or wood trowel, which won't interfere with curing. Work the trowel in a fanning motion to blend the edges with the existing concrete. Do this several times as the mix cures. To burnish the surface very smooth, use a steel trowel (shown) on the final few passes. For a texture, pull a damp push broom over the concrete. Wait at least 24 hours before walking on the patch and a week before driving on it.

Tip: The temperature of the existing concrete must remain above 50 degrees for the first 24 to 48 hours after the patch is applied. The cooler the weather, the longer the curing time.

Simply pouring wet concrete into a hole in your driveway, sidewalk, or basement floor won't make for a lasting repair. You have to prep the edges correctly and use the right materials. Holes 1 inch or deeper require a concrete mix with coarse, crushed-stone aggregate, which bonds well with existing concrete. Shallower holes need a sand mix. Whichever type you use (they're both available at home centers), follow these steps.

1. Use a hammer and a cold chisel to level the bottom of the hole and undercut its sides slightly so the patch can't pop loose. Vacuum, then clean the area with water and a wire brush. Wipe clean.

Patching Holes In Concrete Floors

2. Brush on a concrete bonding liquid, sold in bottles at home centers.

3. While the bonding agent is still tacky, mix the concrete with water and scoop some into the hole. Press it into the corners and against the edges with a trowel. Now fill the hole completely, leaving some material mounded on top.

4. Level the patch with a straight-edged board at least a foot longer than the width of the hole. Move it back and forth in a sawing motion. This will also push down the aggregate and make the final smoothing easier. When the surface loses its wet sheen and feels firm to the touch, smooth it with a magnesium or wood trowel, which won't interfere with curing. Work the trowel in a fanning motion to blend the edges with the existing concrete. Do this several times as the mix cures. To burnish the surface very smooth, use a steel trowel (shown) on the final few passes. For a texture, pull a damp push broom over the concrete. Wait at least 24 hours before walking on the patch and a week before driving on it.

Tip: The temperature of the existing concrete must remain above 50 degrees for the first 24 to 48 hours after the patch is applied. The cooler the weather, the longer the curing time.

OTHER VIDEOS

How to Remove a Burn Mark from a Hardwood Floor

More in Floors

TV Listings

Description

Large Concrete Hole Repair and Thick Concrete Patch Product – Deep Patch™ by SureCrete

Large Concrete Hole Patching and Thick Cement Repair Product – Deep Patch™ by SureCrete

Deep Patch™ is a just add water concrete patch for large concrete voids or holes. Performing well in filling low spots on horizontal surfaces and filling open areas (e.g. planters). The silicate aggregate size will cut the usual shrink cracks associated with topping mixes used for concrete repairs. Contractors and DIY homeowners alike will want to take advantage of the benefits of Deep Patch™ for their many concrete patching projects. It can give a suitable alternative to destroying old, damaged concrete and having to repair a new slab entirely. This product will allow the applicator just to remove the concrete areas that are too damaged to repair and fill in those voids instead of replacing the entire substrate.

Contractors will speed up a restoration process, as instead of having to wait 28 days for a freshly poured concrete to cure, most of all, customers can start applying a finished flooring product on top of Deep Patch™ the very next day.

Deep Patch™ a Thick Concrete Repair Product – Typical applications:

- Kitchen Floors

- Bathroom Floors

- Shower Floors

- Residential Living Area Floors

- Walkways

- Parking Garages

- Thick Concrete Repair

- Patio Floors

- Pool Decks

- Driveways

- Sidewalks

- Commercial Floors

- Large Concrete Hole Repair

- Home Concrete Cracks

How to Apply SureCrete Deep Patch™ Concrete Hole Patching Leveling Material?

- Clean the surface – Concrete substrate should be completely clear of any grease, oil, old paint, etc. Otherwise it will not form a good bond.

- While not always necessary, some areas may need profiling if they are exceptional “tightly trowelled.” Easily be done with another of our Surface Preparation products – SCR.

- Dampen the surface of the concrete (no puddles, though!). Then apply a thin coating of SureBond (associated product used as a bonding agent, mixed with water, sold separately) to a small work area so as not to let it dry out.

Mix Deep Patch™ with water thoroughly in a large bucket. While working to ensure it does not set up before it can be applied.

- Apply Deep Level to ONLY the work area where SureBond is present, not dry. Continue following these steps until all sectors have been patched/covered to your satisfaction! Deep Level is typically trowelled into place; however, application methods will vary depending on the project needs.

- Patches in excess of 2” (5 cm) up to 4” (10cm) require the introduction of # 8 pea gravel (3/8 – ½” [9.5 – 12.7 mm]) at the rate of 10 pounds (4.5 kg) pea gravel to 1 – 50 pound (22.7 kg) bag of Deep Patch™.

Base Coat

1. Before applying Deep Patch™, the surface should be saturated surface dry with clean water (SSD or damp, no puddles).

2. Apply SureBond™ according to the TDS Deep Level

Patching Coat

1. While SureBond™ is still wet, use Deep Level™.

2. Apply Deep Patch™ by trowel or squeegee, ensure the product is tightly placed into patched area.

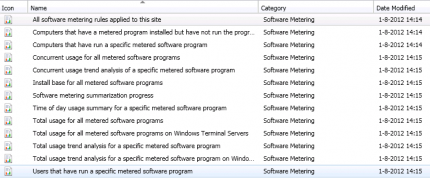

Software metering in Configuration Manager includes a number of built-in reports which allow you to monitor information about software metering operations. These reports have the report category of Software Metering. For more information about how to configure reporting in Configuration Manager, see Reporting in System Center Configuration Manager.

Frequently Asked Questions About Deep Patch™ Large Concrete Hole Repair

Question: How thick can I go with Deep Level Large Concrete Hole Repair?

By itself, we do not suggest going any thicker than 2″ to repair holes. However, with small pea gravel aggregate into the mix, that may be stretched and to as much as 4″. See the TDS for specific instructions on this application method

Question: What’s the thinnest I can go with Deep Level Concrete Hole Repair? Can I give it a feather edge?

This product was not designed to be able to give a tight, feathered edge, or a finished surface. The aggregate size is quite large; the thinnest is can be applied 1/8″. If a smoothing feathered repair concrete finished edge is desired, try using one of our other products such as FlashPatch™ or SureTex™ with Deep Level.

Question: How long do I have to wait before applying an overlay on top of Deep Level Concrete Thick Repair?

While an overnight cure of 12 hours, enough for most coatings systems, depending on the thickness that Deep Level was applied, we suggest waiting a concrete setting full 24 hours before putting any overlay or surface on top of a new Deep Level application.

Question: Can Concrete Deep Hole Filler and Repair Cracked be Colored?

Yes. However our coloring systems matching color charts have formulated based on white-cement-based products, so we cannot offer a typical color chart picking and choose the finished color from, they will almost seem different in Deep Patch™ since it is a grey-cement-based mix.

Specifications – Properties of Deep Level Concrete Deep Hole Filler

Fixing Cracks In Concrete Basement Floor

| Coverage | 0.46 cubic feet per 50 lb bag |

| Shelf Life | 12 months in unopened package |

| VOC Rating | 0 g/L |

| Compressive Strength | ASTM C 109: 24 hours = 3,130 PSI (21,581 kPa); 28 days = 5,000 PSI (34,474 kPa) |

| Tensile Strength | ASTM C 109: 1 day = 280 PSI (1,931 kPa); 28 days = 890 PSI (6,136 kPa) |

| Flexural Strength | ASTM C 348: 1 day = 210 PSI (1,448 kPa); 28 days = 550 PSI (3,792 kPa) |

| Abrasion Resistance | grams lost @ 1/4″ (0.635 cm) thickness: 24 hours = 1 gram; 7 days = 1 gram |

Patching Cracks In Concrete Floor In House

Deep Patch™ is thick concrete repair product Deep Concrete Patch Repair SKU: 15101001 UPC: 842467102206